Experience Superior Security With Ceramic Coatings: an Extensive Overview

Ceramic layers have emerged as an innovative service for those seeking enhanced security for automobile and commercial surfaces. As we check out the complex advantages, application strategies, and just how they pile up against traditional options, it ends up being obvious that the investment in ceramic finishings could redefine your method to surface area defense.

What Are Ceramic Coatings?

Ceramic coatings are innovative protective layers related to surface areas, largely in vehicle and industrial applications, to boost durability and resistance to ecological aspects. Made up of silicon dioxide (SiO2) originated from all-natural products, these coatings form a strong, hydrophobic layer that bonds chemically with the substrate, creating a resilient guard against different aggressors such as UV rays, chemicals, and physical abrasions.

The application procedure commonly entails complete cleaning and preparation of the surface area, followed by the specific application of the ceramic finishing. As soon as healed, the finishing hardens right into a long lasting layer that can dramatically expand the life expectancy of the surface area it secures. Unlike standard waxes or sealants, ceramic layers use a resilient service that needs minimal maintenance.

These coatings are not limited to automotive surfaces; they are additionally used in marine, aerospace, and commercial setups, where they provide considerable advantages in regards to performance and durability. Their adaptability and performance in safeguarding surface areas against wear and tear make ceramic layers a significantly prominent option for both specialists and lovers looking for to maintain the honesty and look of beneficial assets.

Benefits of Ceramic Coatings

Additionally, ceramic finishes show excellent hydrophobic homes, permitting water and other liquids to grain up and roll off surfaces - Orlando Car Care Ceramic Coatings. This self-cleaning effect dramatically lowers the moment and effort required for maintenance, as dust and gunk are less most likely to adhere. Additionally, ceramic finishes are resistant to etching and scraping, which further protects the integrity of the underlying surface

An additional vital advantage is the thermal resistance offered by ceramic finishings, which can withstand high temperature levels without degrading. This quality is specifically advantageous for vehicle applications, where engine components and exhaust systems undergo extreme warm.

Application Process Clarified

Accomplishing optimal results with ceramic coverings requires a precise application procedure that makes certain proper adhesion and performance. For automobile applications, paint improvement might be essential to address flaws, making sure the surface area is as flawless as feasible.

As soon as the surface area is prepared, it is vital to apply the ceramic finish in a regulated environment, preferably in a garage or shaded location to stay clear of straight sunlight and dirt. Utilizing a foam applicator or a microfiber cloth, the coating should be applied equally in tiny sections, permitting ideal control throughout application. A curing time of around one to two hours is suggested prior to subjecting the surface to dampness.

After the first curing, several layers might be used to boost toughness and gloss, with each layer requiring adequate treating time. It is critical to check the surface area for any high places or irregular application and to rub these areas as essential, ensuring a remarkable finish that makes the most of the safety benefits of the covering.

Maintenance Tips for Long Life

Proper maintenance is necessary to optimizing the long life of ceramic layers, making sure that the protective layer proceeds to execute efficiently over time. Routine washing is critical; make use of a pH-balanced, gentle soap and a microfiber clean glove to avoid scraping the surface area. It is advisable to clean the vehicle every 2 weeks or more regularly if subjected to extreme aspects.

After cleaning, completely dry the surface area with a clean microfiber towel to stop water places. In addition, using a ceramic upkeep spray every couple of months can renew the covering's hydrophobic residential properties, boosting security against impurities.

Prevent utilizing abrasive cleaning devices, waxes, or sealers that may deteriorate the ceramic layer. Instead, select non-abrasive products specifically created for ceramic coatings.

Inspect the layer occasionally for any signs of wear or damages, and address these concerns quickly to keep optimum performance.

Contrasting Ceramic Coatings to Alternatives

Keeping ceramic finishes is just one element to consider when evaluating protective choices for vehicle surfaces. When contrasting ceramic layers to choices such as wax, sealants, and paint protection movies, a number of important variables emerge.

Paint security movies (PPF) are another popular option, supplying exceptional physical security versus scrapes and chips. They can be a lot more expensive and might call for expert setup, unlike ceramic coverings, which can usually be applied by a skilled Do it yourself lover. Furthermore, ceramic coverings improve the lorry's gloss and deepness, providing visual advantages that options may not match.

Conclusion

Finally, ceramic coverings represent a considerable innovation in surface area security for vehicle and commercial applications. Their special make-up provides exceptional longevity, hydrophobic residential properties, and resistance to different environmental aspects. With marginal upkeep demands and durable efficiency, ceramic layers not only protect the integrity of surface areas but likewise boost their visual allure. Because of this, they emerge as a practical option for businesses and people looking for exceptional security and longevity in surface area treatment solutions.

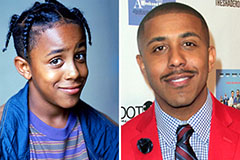

Marques Houston Then & Now!

Marques Houston Then & Now! Julia Stiles Then & Now!

Julia Stiles Then & Now! Shannon Elizabeth Then & Now!

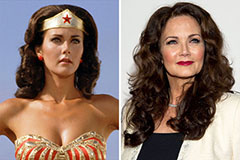

Shannon Elizabeth Then & Now! Lynda Carter Then & Now!

Lynda Carter Then & Now! Naomi Grossman Then & Now!

Naomi Grossman Then & Now!